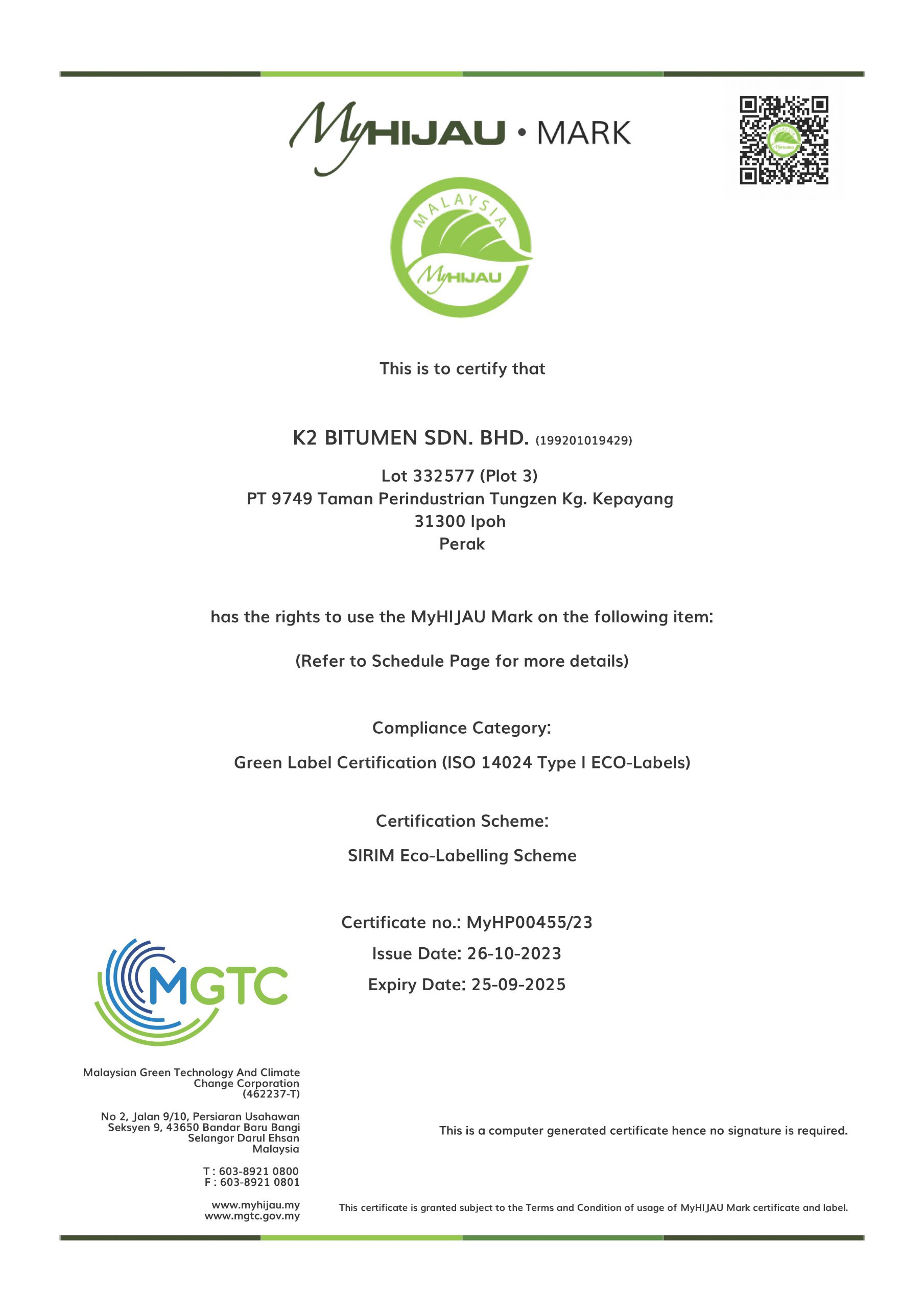

K2 Bitumen Sdn. Bhd. is in the business of producing superior quality, high performance Crumb Rubber Modified Bitumen (CRMB) with the unique formula designed to provide safer, quieter, longer lasting road surfaces to meet the demands of increased traffic and load pressures.

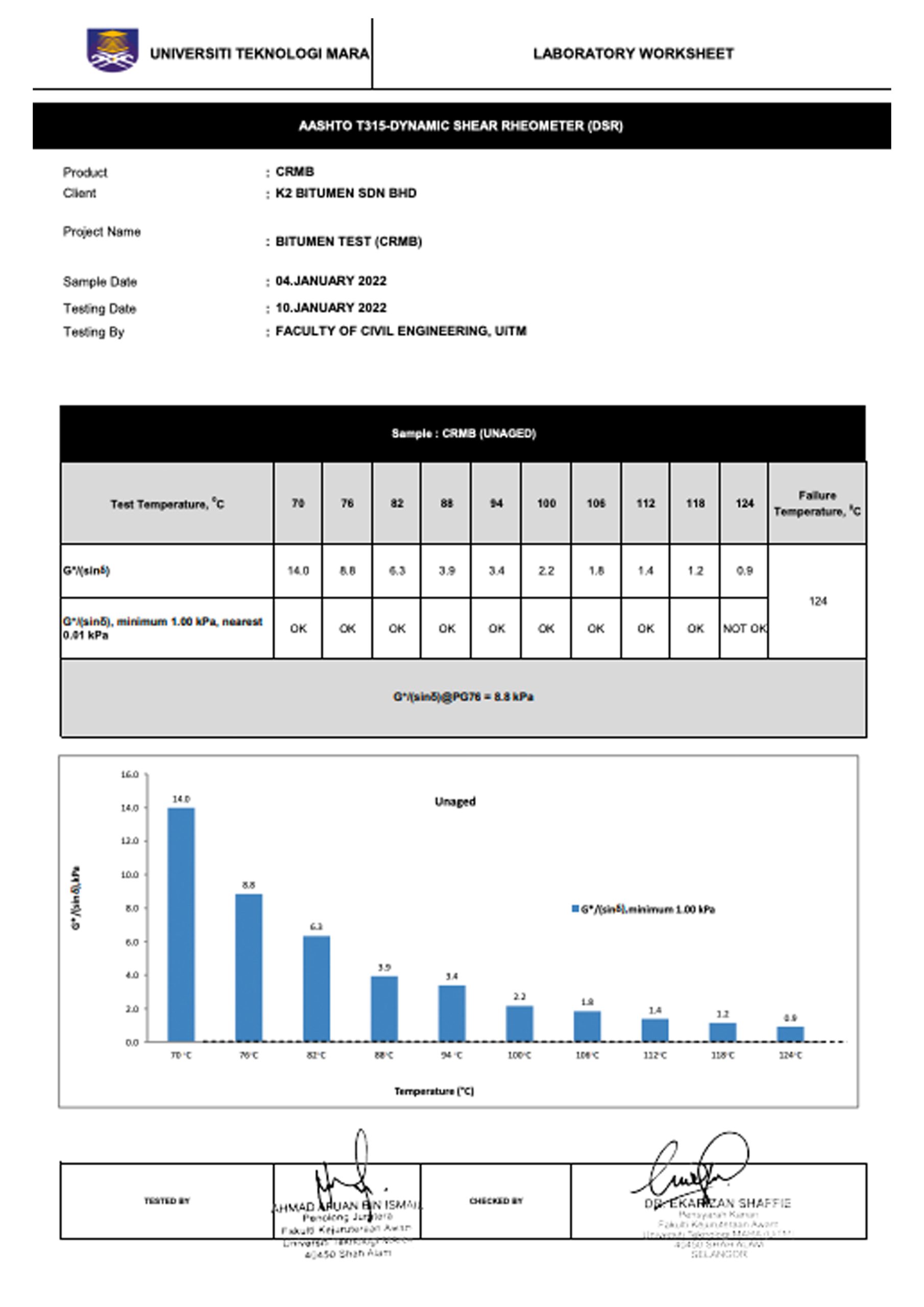

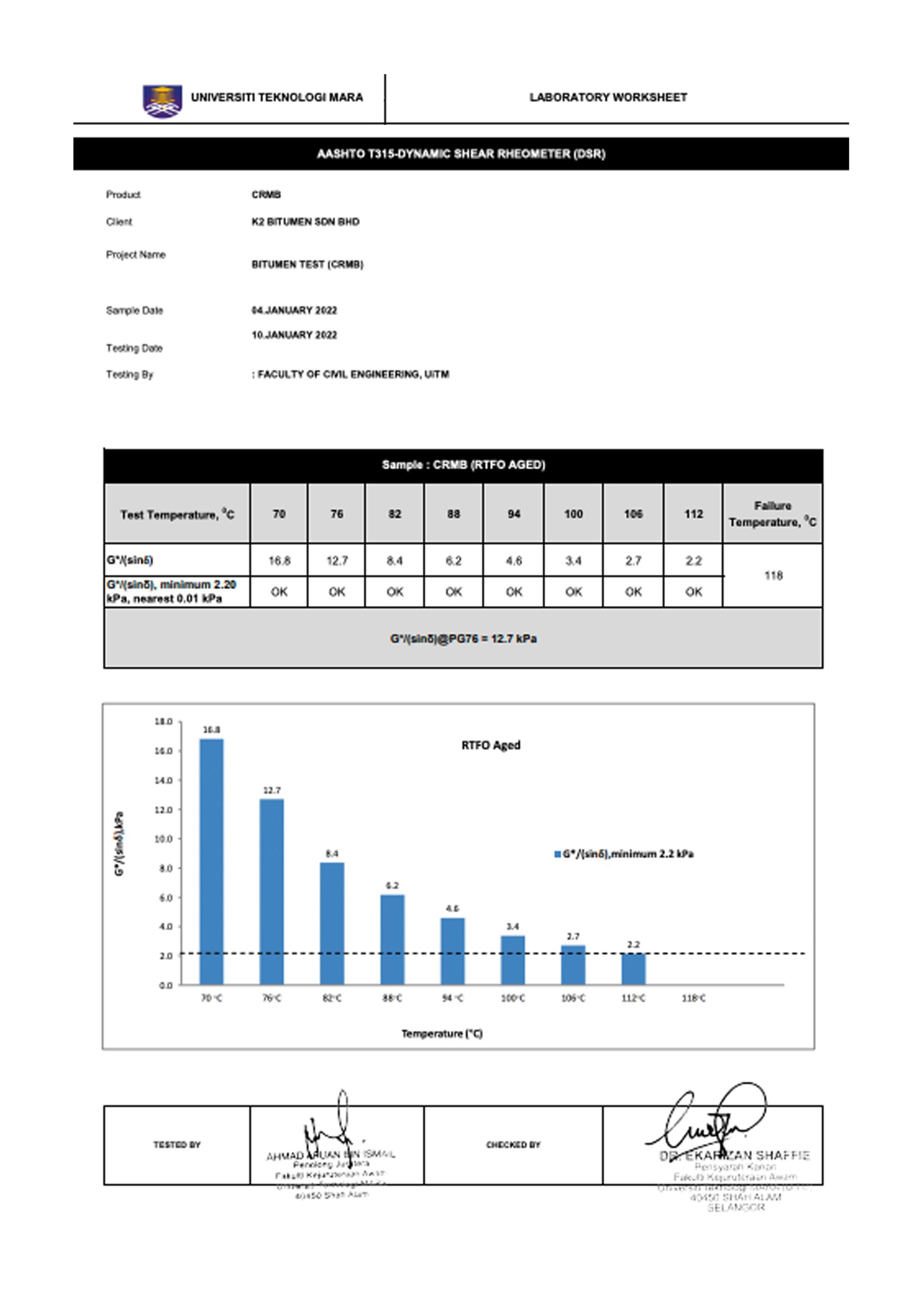

Our CRMB is able to meet and exceed the required performance by achieving better bonding properties, better viscosity and elastic recovery, enhanced flexibility and stability, higher resistance to cracking and rutting leading to better durability even in extreme weather conditions and heavy traffic. It is well suited for high ambient temperature climates like Malaysia that requires materials that have the properties to remain stable and resistant to deformation in high heat.

Through the application of this technology that recycles used tyres, K2 Bitumen is contributing in effectively reducing environmental pollution from burning of discarded used tyres and the prevention of potential hazards of fire disasters and secondary pollution.

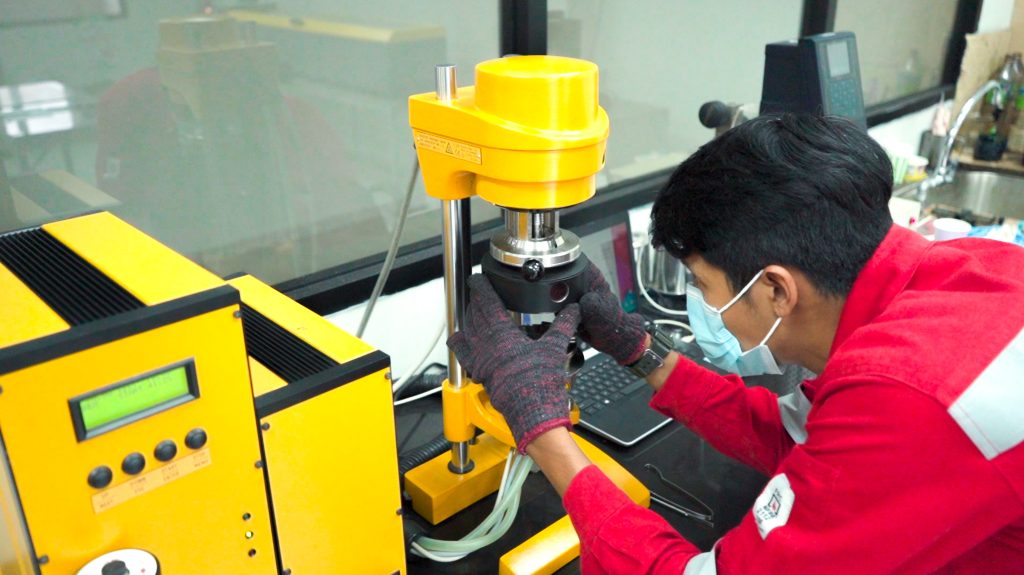

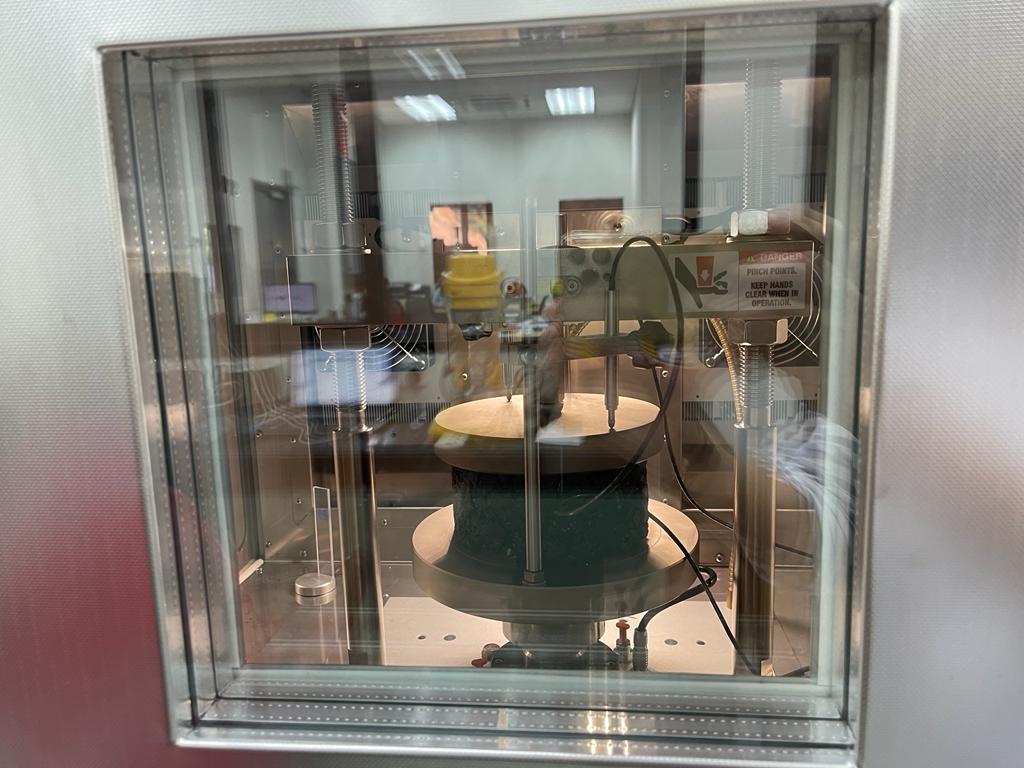

All these achievements are attributed to the time, efforts and substantial investment into R&D before we can attain this immensely successful product. Armed with the available advance equipment and technologies, K2 Bitumen will continue to conduct R&D for new products.