Exploring The Effectiveness of Crumb Rubber Modified Asphalt (CRMA): A Comprehensive Overview On Submerged Roads In Malaysia

Samsul Jaharudin*, Ekarizan Shaffie*, Norshahriah Bahari

1 K2 Bitumen Sdn Bhd, Puchong, Selangor D.E., 47180, Malaysia

2 Institute for Infrastructure Engineering & Sustainable Management, Universiti Teknologi

MARA Shah Alam, Selangor D.E., 40450, Malaysia

3 School of Civil Engineering, College of Engineering, Universiti Teknologi MARA Shah

Alam, Selangor D.E., 40450, Malaysia

*samsul@kemakmuran.com.my & eka@uitm.edu.my

Abstract: As Malaysia is located within the equatorial region, heavy rainfalls and thunderstorms are common occurrences, often leading to flooding that affects the extensive road network in the East Coast of the Malaysian Peninsular. Some flooding involves stagnant water that may remain for several days before subsiding. The impact of moisture on the pavement surface is extensively documented with damages often includes stripping of the asphalt due to the compromised properties of the bitumen. This study aims to evaluate the effectiveness of the “special mix” bitumen known as Crumb Rubber Modified Bitumen, CRMB, as a replacement for the existing bitumen grade against moisture induced damages.

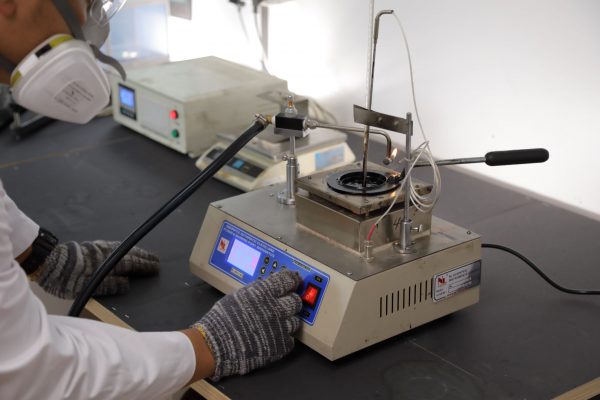

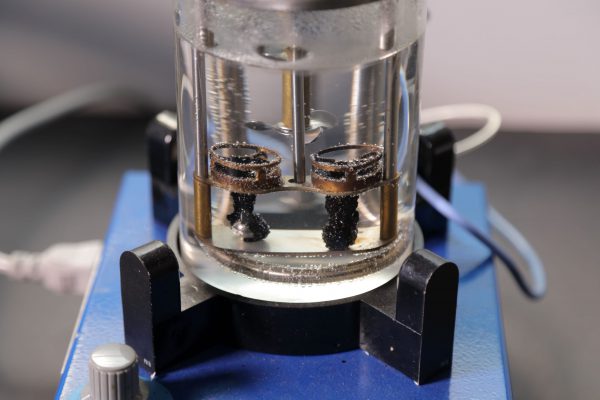

Test samples were collected from flooded affected areas namely Federal Road FT 02 Sec 321, Sec 331 and FT 62 Sec 0 with two of the areas flooded twice within the same year. Core samples from FT 222, Sec 0, using conventional bitumen, were also tested as a control sample. The roads were maintained using two methods, Mill & Pave (MP) 50mm and Overlay 50mm. Maintenance work was conducted in different years to ensure a more comprehensive analysis. The moisture susceptibility test (AASHTO T283) was used to compare the performance of CRMB against conventional bitumen.

The findings indicate that the CRMA with Mill and Pave 50mm (Section 331) shows the highest moisture re-

sistance with a TSR % of 92.6%, making it the most effective for flood-prone areas. In contrast, the CRMA overlay and AC 14 with Mill & Pave 50mm treatments perform poorly, with TSR % values of 45.4% and 45.2%, respectively. This highlights the benefits of CRMB in enhancing road durability in areas prone to heavy rainfall and flooding. This improvement is critical for enhancing the longevity and safety of road networks in such regions, potentially leading to reduced maintenance costs and disruptions.